April 5, according to media reports, a document submitted by Apple to California this week shows that more than 600 employees in California will be laid off. It is understood that most of the laid-off personnel are related to the auto project. Among them, at least 87 people have worked in Apple’s secure facilities for the development of the next generation of screens, while the rest are mainly concentrated in buildings related to the auto project. At present, the official has not responded to this news.

In fact, it is not surprising that Apple has made the decision to lay off employees related to the auto project. At the end of February this year, Apple internally decided to put on hold and cancel all development plans for self-driving electric vehicles, shifting its focus to generative artificial intelligence. This decision means that all work on the Apple car project will come to a halt, and team members involved in the car project will naturally face either a job transfer or a layoff.

In March, it was reported in the market that some employees of the Apple car project will be transferred to Apple’s artificial intelligence department, and some will be transferred to the software engineering department. Apart from the transferred staff, there are still hundreds of members who will face unemployment. Regarding the reason for giving up the car manufacturing plan, there are doubts among Apple’s senior management about the direction of the car manufacturing project and cost control, which has led to the ultimate suspension of the car project.

According to the information, the idea of Apple’s car manufacturing originated from Steve Jobs, and the car manufacturing plan started in 2014. During this period, Apple has invested billions of dollars and recruited many core executives from companies such as Google, Mercedes-Benz, and Tesla. These include former Apple design director Jonathan Ive and the original iPod director, Steve Zadesky. Unfortunately, the progress of Apple’s car manufacturing has not been smooth. Not only are there no specific car manufacturing plans, but there are also constant rumors of layoffs and frequent changes in senior management.

In 2018, with the return of Apple senior expert Doug Field, Apple’s car manufacturing was able to resume, but Doug subsequently left. In January 2019, Apple announced the dismissal of 200 employees from the “Titan” project team. In the same year, Apple acquired the self-driving car company Drive.ai and retained dozens of engineers from the company who are engaged in engineering and product design, and also submitted a number of car patents such as remote control and driving cars to the US Patent and Trademark Office. At the end of 2020, Apple was rumored to have placed stocking requirements with Hota, Molex, Hiqin, and Futian and other Taiwanese auto parts factories, and it is expected that the first model will be officially unveiled in the third quarter of 2021.

In 2022, it was once again reported that the Apple car manufacturing team had been disbanded for some time.SkyWind International analyst Ming-Chi Kuo disclosed that if Apple is to achieve the mass production target of the Apple Car in 2025, it needs to complete the team restructuring within the next 3-6 months. In December 2023, it was reported that Apple may abandon the launch of “L5-level” fully autonomous driving cars and postpone the launch of the car to 2026. In January this year, a leak from well-known Apple informant Mark Gurman stated that Apple has postponed the release of smart cars to 2028. In addition, it was also revealed that Apple’s board of directors had put pressure on CEO Tim Cook and other Apple executives several times in 2023 to submit a plan for the development of smart cars.

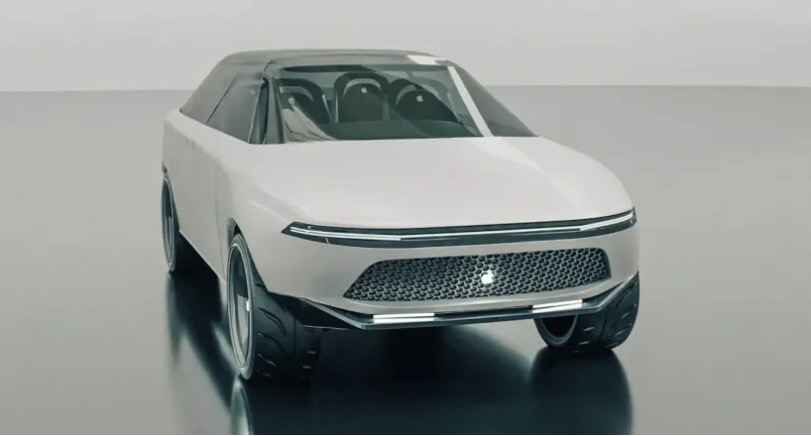

Full of a sense of technology “no steering wheel, no brake pedal”, which used to be the biggest highlight of Apple’s car promotion. However, due to the influence of policies, technologies and other reasons, it is not easy for Apple to realize this idea. Cross-border car manufacturing is already difficult. Apple wants to build a car from scratch. It must be very difficult for Apple, which has no car manufacturing experience. After all, it is more difficult to control the quality of cars than to control the quality of mobile phones. After all, complex cars are related to travel safety, and they also need tens of thousands of parts to be equipped. Furthermore, the large investment and long payback period of this car-building project, coupled with the influence of factors such as the fierce new energy vehicle market and the frequent changes of senior executives, will also inevitably hit Apple’s confidence in car-building.

Even if Apple can go public with Apple Smart Cars in 2028, it will face fierce market competition. For Apple without car-building experience, car-building may not have an advantage. In this way, it may be a good thing for Apple to completely give up car-building. After all, if Apple cars do not have subversive innovation, it will be difficult to gain a foothold in the market, and it is better to continue to focus on the areas they are good at.

As of the closing of the US East Time on April 4, Apple Inc. closed at $168.82, down 0.49%, with a total market value of $2.61 trillion.